FULL VIEW DOORS

WHAT IS A FULL VIEW DOORS ?

The full-view door is one of the most preferred models among the sectional door models and it is the door type that brings your buildings to the fore by providing high-level visuality. It is used as normal lifting, high lifting or vertical lifting according to the beam section of the area to be applied.

Full-view sectional doors are durable and long-lasting doors that are produced to provide the fastest and safest way for today’s modern businesses, especially automotive sales offices and factory entrances and exits. Panels forming full-view sectional doors are produced from 500 mm – 610 mm aluminum finger-protected aluminum profiles.

The standard color of full-view sectional door profiles is natural anodized. However, it can also be painted in the desired RAL colors depending on the exterior color or optional. Full-view sectional doors can also be applied with standard control unit and remote control.

Full-view sectional doors, with the opto laser system feature, allow the door to be opened back in case any object touches it. Full-view sectional doors can be lifted in the form of standard, low, vertical or roof pitch, depending on the detail in the installation location. Thus, the most efficient operation of the door and as little space loss as possible are ensured.

Full-view sectional doors can be manually lifted regardless of the weight of the door, and in case of any power failure or engine failure, the door can be easily used manually or with chain hoist.

Profile thicknesses of full-view doors vary according to the parts used and are specially designed to match each other.

Generally, 3 mm plexiglass glasses are used in full-view doors, and double-glass model with double glazing can be used according to the need. Tempered or laminated glass options can also be applied in different structures in order for our doors to achieve maximum harmony.

Sectional industrial door panels are connected to each other with hinges made of galvanized steel. The wheel sets that provide the movement of the door on the rails are made of noise-canceling polyamide to ensure quiet operation.EPDM seals located between the sectional industrial door panels, on the top, sides and bottom of the door, prevent the passage of dust, air and water and provide a high level of impermeability. The special hollow rubber seal under the door ensures that the door presses softly on the ground, and at the same time, it provides jamming safety with the opto laser system used as standard in motorized doors. With a small touch under the gasket, the door will continue to run in the opposite direction as the lasers cut off communication, and it will not harm you and your vehicles.

Sectional industrial door panels are pulled by winding steel ropes into drums that vary according to the size and lifting type of the door. If the ropes are broken or the springs are broken or damaged in any way, the door is prevented from falling with the rope break safety system and the spring break safety system.In case of power failure, industrial door motor systems are opened manually by unloading the motor shaft or with the help of a chain. It does not require lubrication for lifetime. Meanwhile, even if there is electricity, manual control has priority in terms of user safety.

Full View Door’s Aluminium Profiles

ISO FULL VIEW MODEL PREFERENCES

- Cable break safety system,

- The spring set consists of double springs,

- Spring buffers,

- 2 mm 2 ”galvanized steel rail set,

- Aluminum top sealing profile,

- Aluminum bottom sealing profile,

- EPDM bottom sealing gasket,

- EPDM top sealing gasket,

- Solid shaft with keyway,

- Special aluminium profile wind support sheet is used for doors wider than 5000 mm,

- Single or Double Pleksiglass,

- Spring break safety system (O),

- Rear connection C profile,

- Epdm-Pvc Side sealing gasket,

- After 5000 mm double side hinges and long wheel are used,

- Adjustable double wheel system (O),

- Fixed side hinge system (O).

LIFTING SYSTEMS PREFERENCES

In Full view sectional doors;

Minimum beam spacing for low lifting = 200 mm

Minimum beam distance for standard lifting = 450 mm,

Minimum beam distance for high lifting = Door height + 1000 mm,

Minimum beam spacing for vertical lifting = Door height x 2 space required..

FULL VIEW DOOR'S TECHNICAL PREFERENCES

ALUMINUM PROFILES (For Full View Doors);

- Profiles should be compatible with 40 mm panels,

- It should be compatible for panoramic glass sections,

- 6mm plexiglass should be suitable for single glass systems,

- Aluminum reinforcement profile should be applicable,

- Plexiglass single glass glasses should be 3mm thick and double glasses should be 3 + 12 + 3 thick,

- Aluminum profiles should be able to be painted in all RAL colors.

- The size of aluminum profiles should be adjustable as 500 mm and 610 mm.

• Isodoor panels were tested in Europe at 2019 according to the ISO EN 13241-1 quality management system by SP company and has been successful.

• The door panels are 40 mm thick (0,5 mm galvanized steel + 50 m3 polyurethane + 0,5 mm galvanized steel)

• There are weatherstrips between the two panels.• Inner and outer sheets of the panels are fixed to separation

• Two panels are joined by hinge and have been the integral structure

• Polyurethane CFC free and protects your door of mildew and bacteria • Heat transfer coefficient of the panels are 0:50 W / m² • C.

• Polyurethane filler density of 50 m3

• Polyurethane fillers average thermal conductivity of 9,97 C degrees at 0,017Kcall/(m.K)

• Wind resistance of polyurethane filler is EN 12444, 12427 Std, Class en 12424 and Class3

• The waterproofing value is EN 12425 class2.

• Air permeability value is EN 12426, EN12427Std, class EN12424 class3.

• Panels has a finger-safe protection.

• Weight of panels are 11 kg/m2•

• When the doors length higher than 6 m, reinforcment profile are used on the doors.

• Spring are galvanized or painted.

• Cable is cut to lenght and assembled Aircaft, 6×19=114 steek wire with PP core

• The shafts used in door are galvanized.

• Spring wire has after coiling , received heat treatment.Also available in power coated or natural And fix-to-size assembled.

• Door rails and brackets , made of 2 mm galvanized metal• Door rail profile has a special twist.This twist keeps wheel in the rail.

• Bracket and rail profile are connected to the pneumatic clamping and It has strong structure.

• Wheells which is located in the rail an edge of the doors are fabricated by polyamid and these polyamid prevents noise.

• Doors have opto-laser safety systems which is bottom of doors in plastic gasted. When doors are closing, if you have small soft touch, door can open to up side.

• There is a combination section that is located between door panels and is useful for impermeability and also there is a rubber seal though integrated panel.

• A rubber outer seal ring with double-lipped which is useful dor impermeability and also protects flexibility until 30 degree is located between door panel and upperwall and sidewall.

• There is a special porus flexible roving which provides impermeability between door panel and floor and it enables the door to lock on the ground and also this roving is situated into profile of the door’s lower panel.

Industrial Door Openers

There are many different models of motors and bottom-safety systems to be used in industrial doors. You can choose accessories according to your needs.

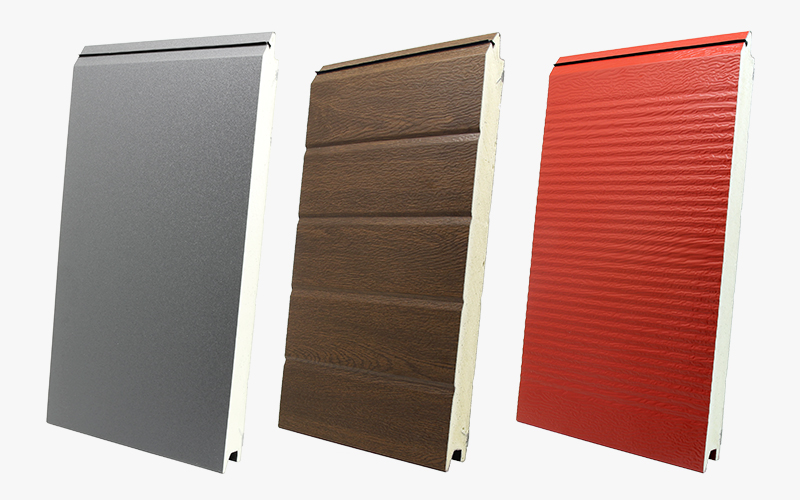

Sandwich Panel Models

Sandwich panels can now appear to be fully compatible with these structures. With different models and colors, industrial and garage doors gain a modern look.

Sectional Door Hardwares

Approximately 35 different pieces of products are used in sectional doors, depending on the dimensions. These parts are sent ready for assembly.